Compressor Wheel Fatigue

If the compressor wheel material is not as strong as it should be, the centrifugal force will cause the material to flow away from the centre. At these high speeds the natural grains of the surface material are unable to cope. This can cause what is known as the ‘orange peel’ effect which is often associated with overspeeding.

Fatigue – Understanding Endurance Limit

When a compressor wheel has been weakened, it will begin to show signs of fatigue. For example, if you bend a piece of Aluminium backwards and forwards enough times eventually it will break.

In terms of the compressor wheel fatigue, the blades are exposed to a continuous cycle of positive and negative stress caused by the wheel spinning fast and then slow. As the compressor wheel reaches full speed, the blades bend backwards and then as it slows down they bend back into position. Repeat this over many repetitions and suction is created, which creates negative stress pulling the blades even further in.

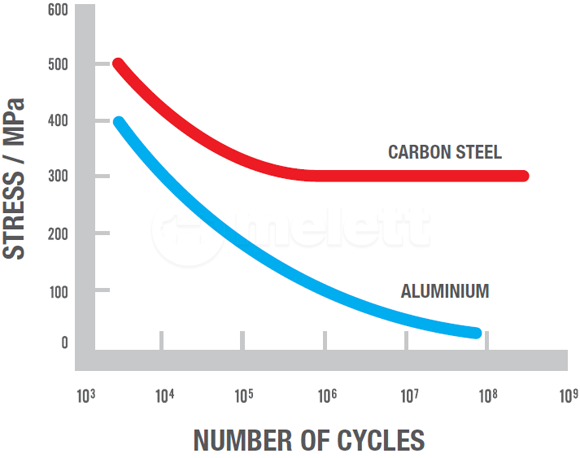

Eventually the continuous stress will become too much and the blades will reach their endurance limit, and break causing the turbocharger to fail. Therefore, if the strength of the material is a lot lower than it should be the compressor wheel will break from fatigue a lot earlier than if a stronger wheel had been used. Using a stronger compressor wheel will ensure the blades do not move as far, reducing the risk of fatigue and failure.