Common turbo failure – oil contamination

Common causes of oil contamination:

Oil is very often overlooked as a critical component. However, clean filtered engine oil is a major requirement and a necessity for all turbochargers.

View our Melett Turbo Tips video - How does oil contamination cause turbocharger failure?

Welcome to our latest Turbo Tips Video – Oil Contamination – One of the main reasons why turbos fail.

What is oil contamination? Oil contamination is when the oil that flows through a turbocharger becomes contaminated.

Today’s video will highlight the causes, signs and preventions associated with Oil Contamination.

What causes Oil Contamination? We have picked out a few here but there are many more in our help guides.

One of the causes is poor quality or damaged oil filter.

Carbon build-up or swarf deposits from the engine

Carbon from the oil feed pipe

Or, blasting residue from the reman process

Damaged oil filter

Carbon build-up

Carbon from the Oil Feed Pipe

Blasting Residue

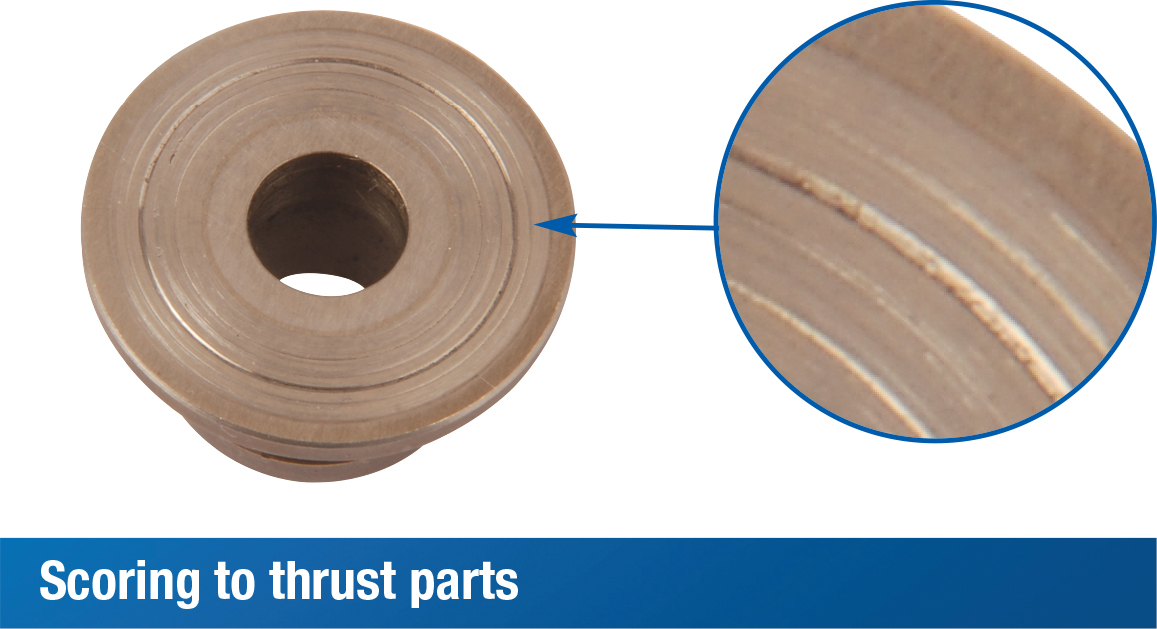

Here are the signs Oil Contamination leaves on the turbocharger shaft & wheel

If the oil is contaminated, score marks will be visible on the Journal Bearing landing areas – as you can see here

There are different levels of damage, here is an extreme case of Oil Contamination

Notice the damage to the Journal Bearing landing areas caused by Oil Contamination

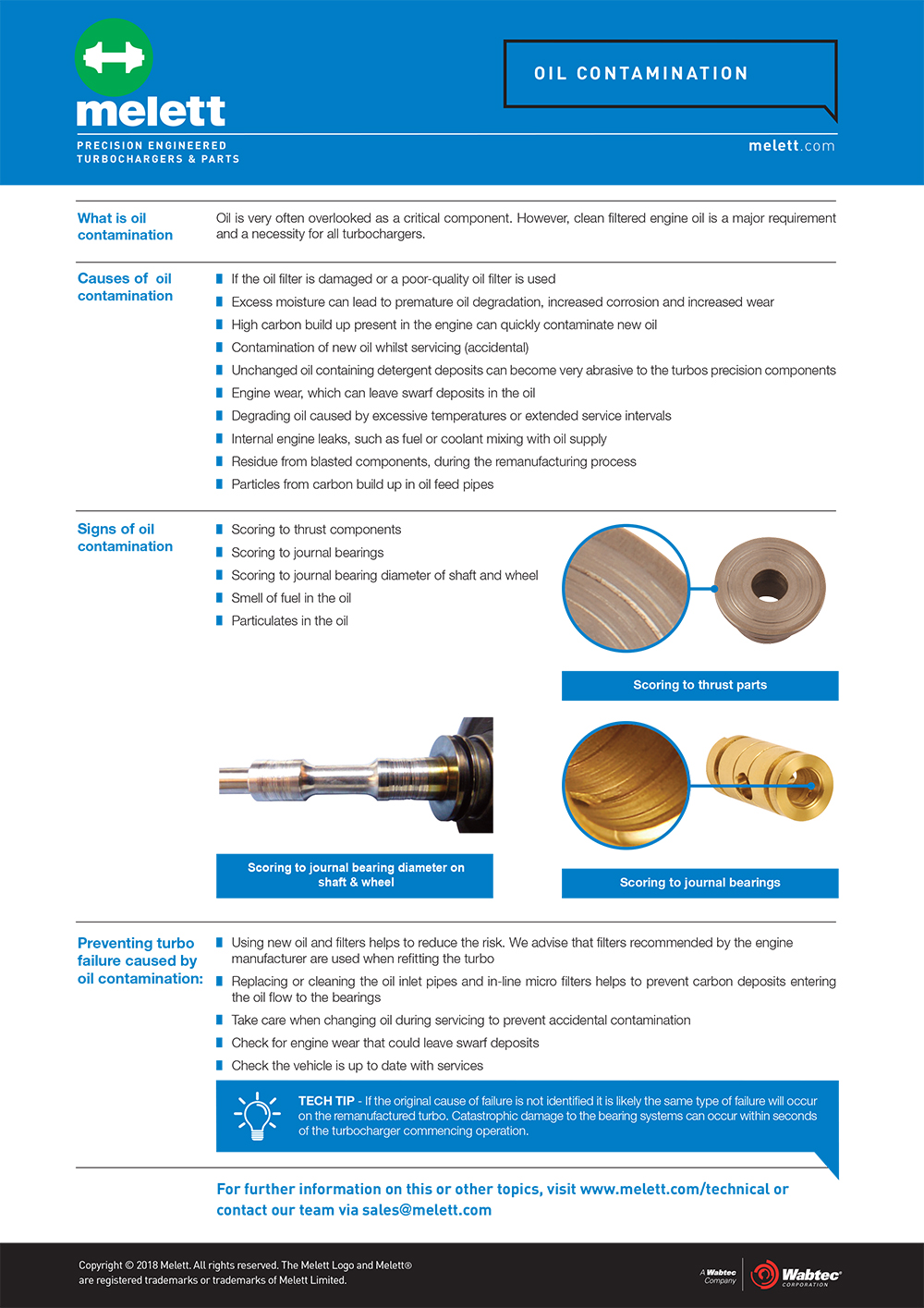

Next, we would look at the Journal Bearing, focusing on the OD and ID checking for any signs of scoring.

On a free-floating Bearing, the OD and ID will be scored

On a fixed Bearing, usually, the ID will be scored

Damaged caused by Oil Contamination on a free-floating Journal Bearing

Here is an example of a Journal Bearing cut in half to show you the score marks inside the Journal Bearing

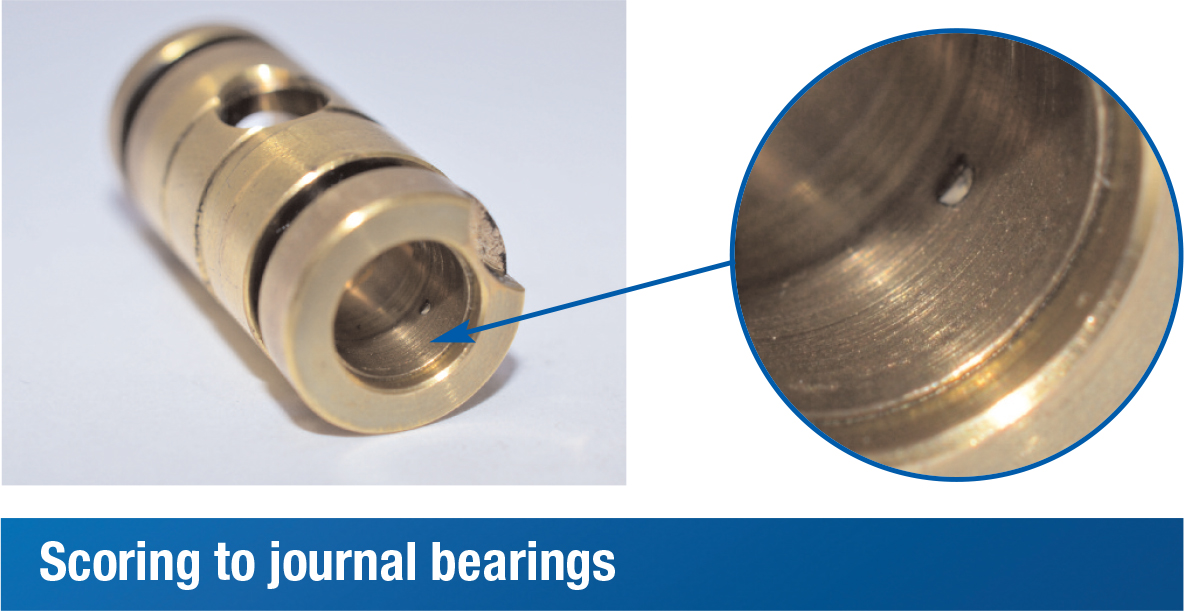

Signs of Oil Contamination can also be found on the Thrust Bearing, mainly on the ramping where most of the oil flows around the thrust set-up.

Let’s take a closer look at the scoring mark on the ramping area, this identifies the failure as Oil Contamination

There are different levels of the damaged caused by oil contamination, there is an extreme example.

Along with the Thrust Bearing the Thrust Flinger, Washer and Collar will show signs of Oil Contamination. Let’s look at these components individually.

Thrust Collar

Thrust Flinger

Thrust Washer

So, we have discussed the causes and looked at the signs, lets now discuss prevention. We have picked out a couple of examples, but for more information, check out our downloadable help guide on the website.

Check your engine for swarf deposits. Take care when changing the engine oil. Always use the recommended oil and oil filters. And, change or clean any oil feed pipes.

Helping you have a longer-lasting Turbocharger.

Check for swarf deposits

Take care when changing the engine oil

Use the recommended oil/filters

Clean the oil feed pipe

Melett Turbo Tip – Always diagnose the original cause of failure, if the original cause of failure was oil contamination and it does not get diagnosed

correctly when you refit the turbocharger it will fail.

Thank you for watching and we will see you next time for another Melett turbo tip video.

Enjoyed our Video? Press the like button, leave us a comment below or subscribe to our YouTube Channel to watch further videos from Melett.

Causes of oil contamination

- If the oil filter is damaged or a poor-quality oil filter is used

- Excess moisture can lead to premature oil degradation, increased corrosion and increased wear

- High carbon build up present in the engine can quickly contaminate new oil

- Contamination of new oil whilst servicing (accidental)

- Unchanged oil containing detergent deposits can become very abrasive to the turbos precision components

- Degrading oil caused by excessive temperatures or extended service intervals

- Internal engine leaks, such as fuel or coolant mixing with oil supply

- Residue from blasted components, during the remanufacturing process

- Particles from carbon build up in oil feed pipes

Signs of oil contamination:

- Scoring to thrust components

- Scoring to journal bearings

- Scoring to journal bearing diameter of shaft and wheel

- Smell of fuel in the oil

- Particulates in the oil

Alternatively, if oil levels are too low or if the wrong grade of oil is used, the turbocharger will also fail. If the original cause of failure is not identified it is likely the same type of failure will occur on the remanufactured turbo. Catastrophic damage to the bearing systems can occur within seconds of the turbocharger commencing operation.

Preventing turbo failure caused by oil contamination:

-

- Using new oil and filters helps to reduce the risk. We advise that filters recommended by the engine manufacturer are used when refitting the turbo

- Replacing or cleaning the oil inlet pipes and in-line micro filters helps to prevent carbon deposits entering the oil flow to the bearings

- Take care when changing oil during servicing to prevent accidental contamination

- Check for engine wear that could leave swarf deposits

- Check the vehicle is up to date with services

For further information on this or other topics, please contact Melett Technical Support – [email protected].